Published 17:18 IST, December 28th 2023

Can India do without Chinese steel?

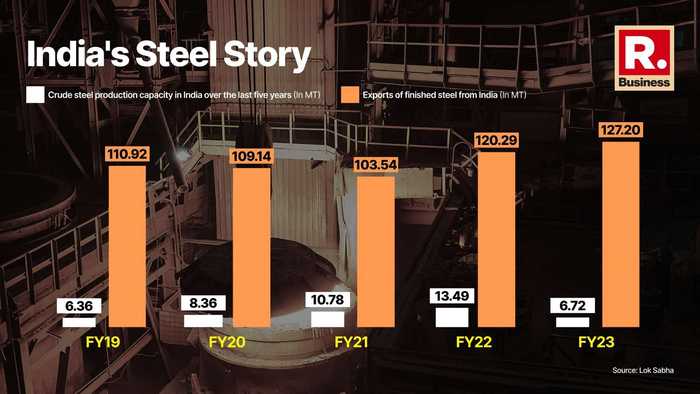

Indian steel sector is anticipated to post double-digit growth at 11-13 per cent for the third consecutive year, driven by the government's massive capex push

Advertisement

It was not long ago, when Chief Executive Officer of Tata Steel, TV Narendran raised concern about rising steel imports in India. concern was valid as predatory pricing from our neighbours was impinging hard on our domestic producers-thanks to China’s galloping steel exports and high price differential between international and domestic steel markets. India, second largest consumer of finished steel in world reported steel consumption of 119.89 metric tonne (MT) and per capita steel consumption of 86.7 kg in 2022-2023.

Source: Republic Business

Advertisement

On flip side, import of total finished steel in 2022-2023 was at 6.02 MT in 2022-2023. steel industry, which is booming like never before, is anticipated to post double-digit growth at 11-13 per cent for third consecutive year, driven by government's massive capex push. sector registered growth of 11.4 per cent in FY22, and 13.4 per cent in FY23, and now experts opine that in FY24, sector is poised to grow upwards of 11-12 per cent again.

Irking Imports

Advertisement

rise in imports is attributed by experts to cheap prices and wide price differential existing between domestic and international steel prices. It's lucrative discounts on hot-rolled and cold-rolled (steel products) that is pushing a lot of buyers from India flocking to sign a flurry of import deals.

As far as imports are concerned, biggest of all is from China. In last 3-4 months, with run rate of 8 MT per month, China is exporting around 100 MT exports annually. As per experts, last time China exported at such levels was in 2015, as it was peak of metal meltdown which plunged entire industry into stress.

Advertisement

“If you look at last 4-5 months, India has been a net-steel importer, if this kind of trend continues, n re is a situation when India can become a net-steel importer for a full year. This is happening for first time in last four years, last time India was net steel importer is in 2019,” person with knowledge of matter told Republic Business.

“HR Coil, electrosteel, electric steel and HR coil are imported because of price differential. When local manufacturers peg prices, y are not in sync with international prices, n imports are encouraged,” Manish Garg Owner, Good Luck Steel, told Republic Business. According to Garg, large producers of HR coil manufacturers in India fix ir prices higher, and immediately re is arbitrage available, so a lot of it gets imported because that is cheaper.

Advertisement

Poised to Post Robust Growth

“Steel sector is seeing fastest pace of growth in last fifteen years,” Ritabrata Ghosh, Vice President & Sector He-Corporate Ratings, ICRA, told Republic Business. sector is looking at this kind of growth in last fifteen years. people keeping a close eye on growth trajectory of sector believe that this kind of double-digit growth was last registered before global financial crisis of 2008.

Source: Freepik

“Just before Lehman brors’ collapse, growth was 13-14 per cent," Ghosh ded furr. Amidst dizzying growth, steel sector is having one big challenge looming large that is to guard domestic producers from rising imports from various markets like China, South Korea, and Vietnam. Similarly, Chinese finished steel imports to India rose sharply by 48 per cent in April- November period to 1.3 million metric tonnes, followed by South Korea.

In dition, various environmental norms have also posed a formidable challenge in front of domestic steel producer. For example, between January-November period this year, exports from China rose 35.6 per cent to 82.7 MT, and exports to India also increased. China has replaced tritional exporters to India in last few months.

As of November, in current fiscal year, India imported 4.26 MT of finished steel, up by 13.4 per cent on a year-on-year (YoY) basis, even as exports dipped 6.2 per cent to touch 4.03 MT, in turn making country a net importer of finished steel. Comparatively, steel imports remained around 5.6 per cent of domestic demand at 6.7 MT in previous fiscal years.

China’s Charming Steel

But key question is why China’s steel hold such charm in India. answer lies in China’s huge coking coal production capacity and vanced technology. According to industry insiders, in India, steelmaker Iron ore is just 12-15 per cent of ir total cost and biggest cost incurred is on coking coal that is around 40-50 per cent of total production cost.

As far as key ingredient for steel production (coking coal) is concerned, India is heavily dependent on imports. On flip side, China has a huge production base of coking coal, making steel production cheaper in China, compared to India. “In China, disvantage is that y don't have iron ore, y actually have to import iron ore, even if cost of importing iron ore may be double but vantage is that 90 per cent coking coal demand is met domestically,” Ghosh of ICRA said. India largely fulfils its coking coal requirements through imports from Australia. But owing to frequent wear induced disruptions, re has been huge fluctuation in coking coal supply as well as coking coal prices. “ cost of steel production in domestic mills goes up in a much bigger way when prices of coking coal go up in Australia compared to Chinese producers. re is a price differential in coking coal from China and or sea borne markets,” Ghosh quipped.

Although India has abundant reserves of iron ore and coal, it has negligible reserves of coking coal. National Steel Policy envisages that India will reach 300 million tonnes of steel-making capacity, and 68 per cent of that will be through blast furnace route, which requires coking coal. This translates to about 200 million tonnes of steel being produced using coking coal, which means an annual consumption of about 180 million tonnes of coking coal.

Secondly, cost of capital has a huge role to play in steel production which is higher in India when compared to its neighbouring countries. Steel is a capital-intensive sector. As per PWC report, nearly Rs 7,000 crore is required to set up one tonne of steel-making capacity through greenfield route. Naturally, cost of financing any expansion or new steel capacity is usually through borrowed capital.

Source: Freepik

And in India cost of finance is extremely high compared to cost of finance in developed countries such as China, Japan and Korea. This ds about $30–35 to final cost of steel. cost of capital in India still remains significantly high and Indian steel makers continue to face a relative disvantage vis-à-vis ir competitors from developed world.

Self-sufficiency in coking coal production, cutting edge technology, along with lower interest rates in China puts country in an vantageous position when compared to India leing to a wide price differential, and which in turn boosting imports from China to India.

But, this October brought a sigh of relief. Since October, price differential has declined. “In fourth week of November 2023, Chinese HRC prices tred at US$565/ MT as against domestic HRC prices of Rs 55,000/MT. Domestic prices were at a US$3/MT marginal discount compared to imported offers in end November. However, in first week of October 2023, before domestic steel price corrections started, domestic HRC prices were tring at a US$60/MT premium over landed cost of imported offers,” Ghosh opines.

“In November we researched and found that gap has been bridged, incentive to switch from domestic to international market is not as high as it was before October,” Ghosh ded furr. This may in future le to lesser imports from China.

Way Ahe

steel sector going through phase of phenomenal growth is staring at a possibility of robust growth only if capital expenditure by government maintains same momentum like ongoing fiscal. steel industry’s capacity utilisation is steily increasing signifying its miraculous growth. Currently, capacity utilisation stands at 83 per cent, highest in dece. According to Ghosh, whenever capacity utilisation increases beyond 80 per cent, you see investment uptick because growth outlook is good, ir balance sheets are delivering.

growth of steel sector in 2024 is riding on back of many things. biggest concern is that in election year government spending may slow leing to a slower growth in domestic sector fuelled by government capex. “In election year, if government spending will not decline, you might see similar growth as usual as capital spending is concerned,” an industry insider told Republic Business. Some experts see growth slower than 2023, but China is crucial for India’s steel sector. Some analysts believe that lag effect of higher interest rates may le to a recession in 2024, leing to a slowdown in steel sector in India.

16:56 IST, December 28th 2023